Avoiding Bad Historic Masonry Advice

Uh oh, there is a problem with your home’s masonry. For many of us, the first place we turn is the internet. The human brain wants to solve problems and so we go searching for answers: what is happening and how can we fix it easily, quickly, affordably, and correctly.

We have seen lots of bad internet advice given by well meaning but uninformed people. So let’s tackle why this advice is to be ignored.

“You can just use a Type N Cement Mortar and Stucco to repoint and parge historic masonry.”

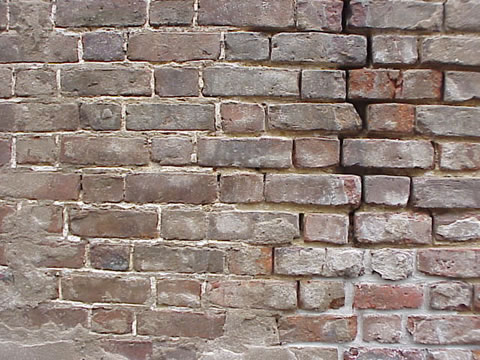

This is one of the most common bits of bad advice that we run across. For professionals and homeowners alike, sourcing the correct lime-based material so that a repair can work as long as the original installation can be difficult. Therefore hearing that an easily found and cheap Type N mortar seems like an easy plan. However, cements are not breathable like lime based mortars and will trap moisture within the masonry, causing damage down the line. Any amount of cement can cause significant problems when the mix is put up against historic lime-built walls that need to breathe. What may be a “cheap and quick” solution at the moment will likely result in very costly repairs to reverse.

If you do want to use lime-based repair materials, know that the lime material provided at big-box hardware stores is typically Type-S hydrated dolomic lime. That material will not result in a quality fix with the durability needed. Type-S hydrated dolomic lime’s main function is to be mixed with Portland cement as a plasticizer and not stand on its own. It won’t to hold up to freeze-thaw cycles when used outside or be robust enough to hold up to natural weather patterns over time like the correct lime-based material would. Saint-Astier® Natural Hydraulic Lime (NHL) will convert back into a stone over time, which is what the historic mortar and parging did that made it durable, but remains breathable and malleable in the first place. Even other NHL’s don’t perform as well as Saint-Astier® Natural Hydraulic Lime which is explained here.

While choosing the proper lime materials may have a higher price tag up-front, the cost of doing it once and doing it right is priceless.

“You need to seal your basement.”

We get it, moisture in your basement is not what any homeowner wants. Basement water sealing or water proofing is a big business and has done a lot of marketing to have consumers think it’s their only option.

When a non-breathing cement mortar or a waterproof sealer (including dry locking coatings such as cement stucco) is ever applied to the interior of a basement then water moves in the capillaries of the bedding mortar to creep upward and can rot the sill plates and joists. Oops. No homeowner wants to cause adjacent failure when attempting to fix one thing and getting a boatload of costly trouble in another place. The same thing happens if using cement pointing or stucco mixes on the exterior of an old mass-wall masonry building built with lime mortar–it can simply trap the water in the core of the wall. If the wall can’t release moisture back to the atmosphere, then water will migrate toward the interior of the building, damaging internal plaster. This is often seen by the resulting bubbling paint and plaster on walls within historic homes.

When moisture becomes trapped inside of a wall, it will travel to the point of least resistance and wreak havoc on all absorptive adjacent materials. Window frames can rot when moisture becomes trapped behind non-breathable coatings like elastomeric stucco. Because the masonry can no longer release moisture naturally, water is redirected toward surrounding materials. The excess moisture, typically above 20%, can create a breeding ground for bacteria so long as there is a food source. Wet walls also take a lot more energy to heat and cool the building. It is imperative to keep your historic masonry building dry within its walls.

Often the solution is within the same materials that a basement was originally constructed with. If you have a lime mortar or render in your basement space, the correct lime as supplied by LimeWorks.us is the material you should repair it with. Just call our helpful technical staff to guide you through your application.

“It’s just at the end of its service life and needs to be torn out.”

There is a story we share at the opening of our Basics of Repointing with Lime Mortar workshop of a mason who attended one of our training sessions and shared some insight. When he was just starting out as a mason in Philadelphia, it was around the Bicentennial Celebration and he worked on repointing many of the historic homes in the colonial neighborhoods of the city. As they worked through the years, he began to notice that many of the homes that were recently repointed with Portland cement based mortars were having issues with the brick, spalling and showing damage.

He asked his supervisor what was going on and the supervisor replied, “oh those are just old and at the end of their service life.” Fast forward to today and there is better knowledge about using lime mortars and preservation, but this mason was kicking himself for all the damage that they unknowingly did.

Conclusion

Ancient mass-wall masonry buildings are still standing world-wide with little intervention being imposed upon them. They keep going and our historic structure will too until someone decides they need to fix the building with inappropriate materials that will only accelerate deterioration or cause adjacent failure. Nothing in masonry “just happens.” Structures have been held together for centuries with lime mortars so ask yourself why now, what happened that caused this damage to begin. When you address the root of the problem and you continue to let the building serve its purpose for decades to come.